Share to

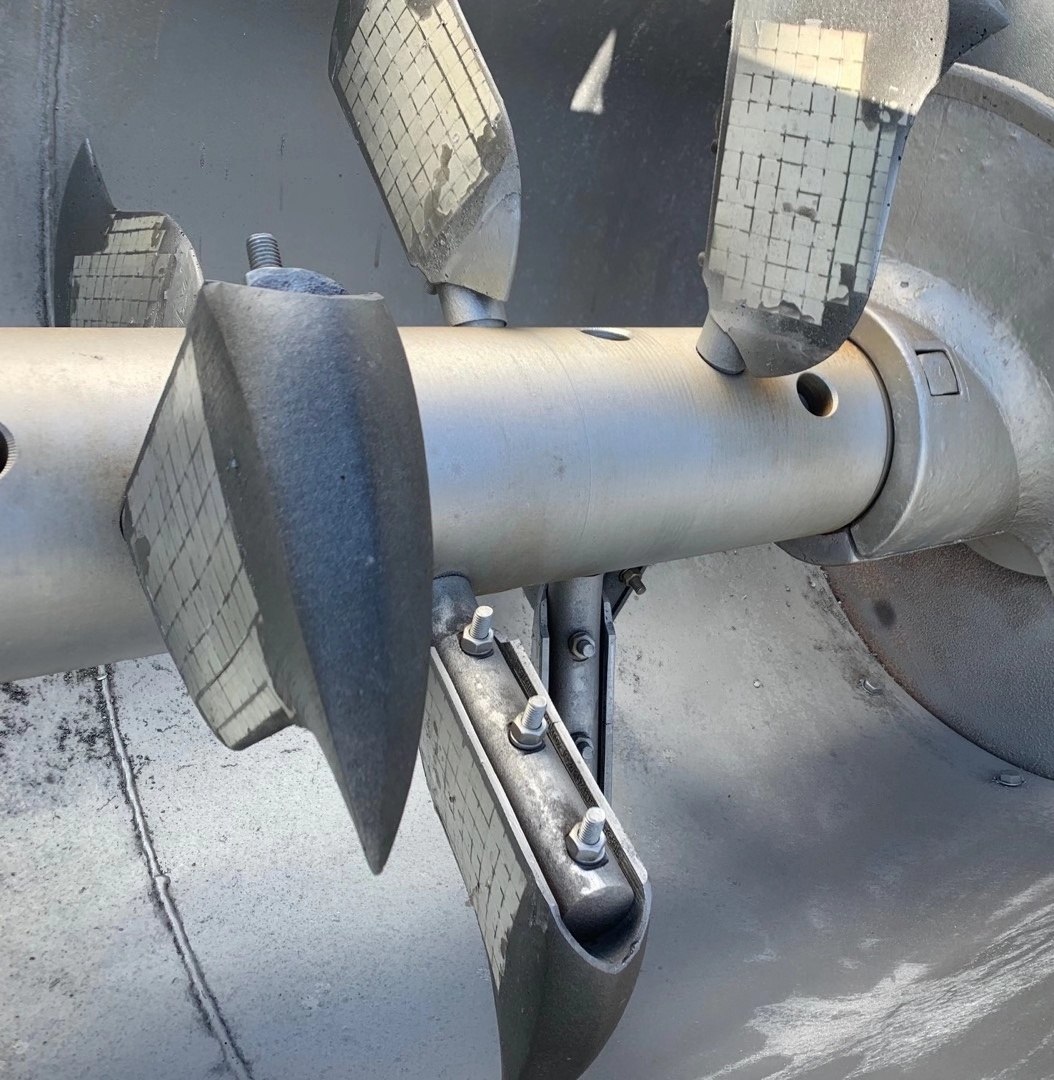

Composite Wear-resistant Die Base

WhatsApp:

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product description

-

The following is the version of RMB converted into US dollars (assuming the exchange rate is 1 US dollar = 7.0 RMB, the actual exchange rate may need to be adjusted according to real-time data):

The following introduction is based on the situation in China, for reference only.

Ceramic Composite Wear-Resistant Die Base

I. Performance Advantages

- Efficient Connection & Energy Saving: Seamless integration with the die, smooth inner surface, reducing operating current by approximately 20A.

- Extended Lifespan: Ultra-high wear resistance, enabling continuous use for three years without replacement.

- Quality Enhancement: Significantly improves the quality of finished brick blanks

II. Economic Benefit Analysis

(Based on a 280kW extruder, 10 hours of daily operation, and 300 production days per year)1. Electricity Cost Savings

- Annual Savings: 20A × 0.6 (power factor) × $0.10/kWh* × 10h/day × 300 days = $3,600

- Three-Year Total Savings: $3,600 × 3 = $10,800

2. Equipment Cost Savings

- Die Base Cost:

$428.57/unit × 2 units/year × 3 years + $128.57/overlay welding × 18 times = $7,200 - TCKD Ceramic Composite Wear-Resistant Die Base Cost:

$928.57 × 3 years = $2,785.71 - Savings: $7,200 - $2,785.71 = $4,414.29

3. Labor Cost Savings

- Maintenance Labor for Normal Die Base:

2 workers × 6 hours × $7.14/hour × 18 instances = $1,542.86

III. Total Comprehensive Savings

By adopting the TCKD modified head, total savings over three years:

$10,800 (electricity) + $4,414.29 (equipment) + $1,542.86 (labor) = $16,757.15

Composite Wear-resistant Die Base

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!